EWM Taurus 405 Synergic S TDM Operations Instructions Page 27

- Page / 50

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

Design and function

Connecting the intermediate hose package to the power source

099-005219-EW501

10.06.2013

27

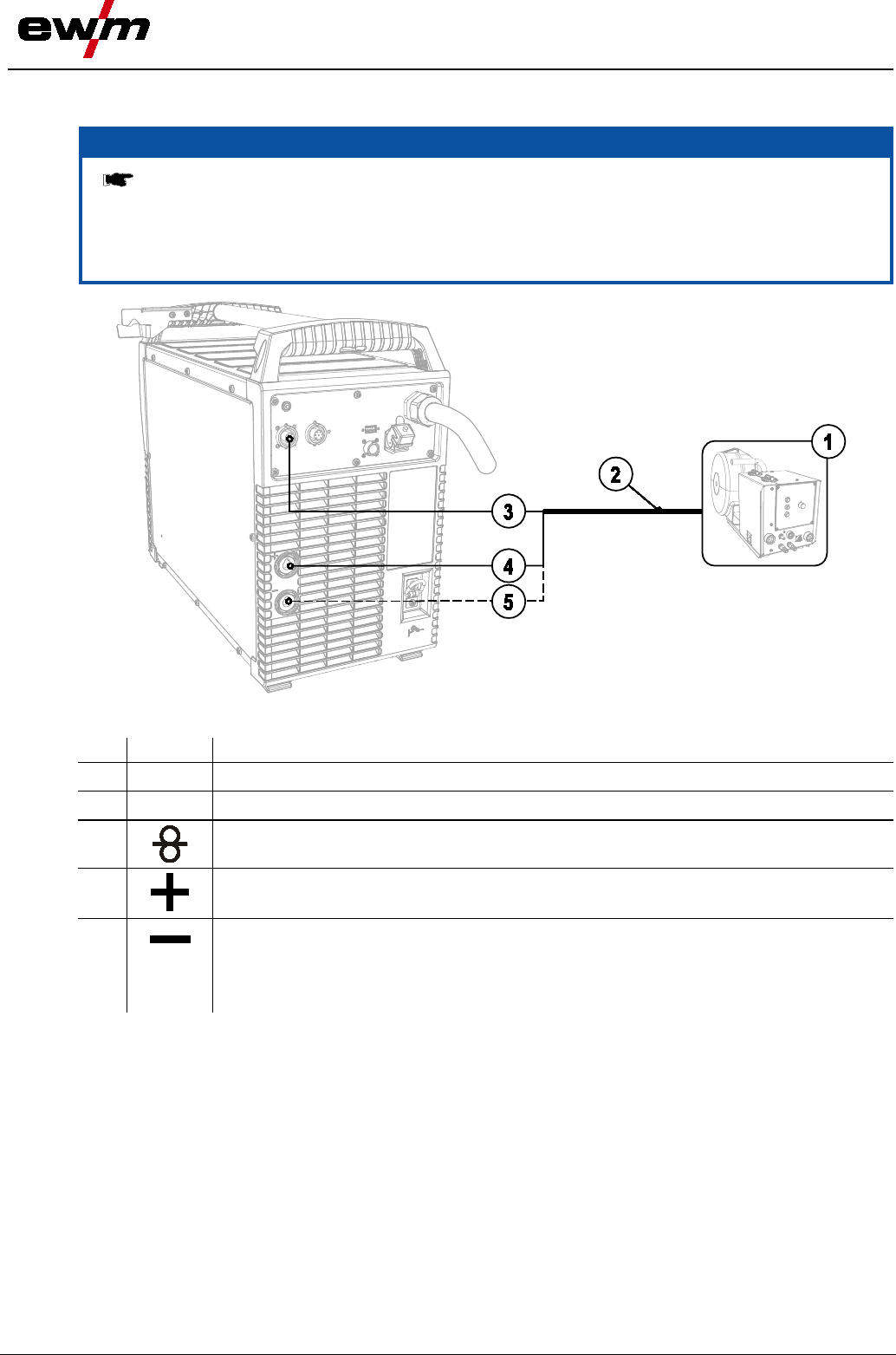

5.8.2 Intermediate hose package connection

NOTE

Note the polarity of the welding current!

Some wire electrodes (e.g. self-

shielding cored wire) are welded using negative polarity.

In this case, the welding current lead should be connected to the "-" welding current

socket, and the workpiece lead should be connected to the "+" welding current socket.

• Observe the information from the electrode manufacturer!

Figure 5-5

Item

Symbol

Description 0

1

Wire feed unit

2

Intermediate hose package

3

7-pole connection socket (digital)

Wire feed unit connection

4

Connection socket, “+” welding current

• Standard MIG/MAG welding (intermediate hose package)

5

Connection socket, “-” welding current

Connection for welding current plug from intermediate hose package

• MIG/MAG flux cored wire welding

• TIG welding

• Insert the end of the hose package through the strain relief of the hose package and lock by turning to

the right.

• Insert the plug of the welding current lead into the welding current connection socket and lock in place

by turning to the right.

• Insert cable plug on the control lead into the 7-pole connection socket and secure with crown nut (the

plug can only be inserted into the connection socket in one position).

- Register now! 1

- For your benefit 1

- Jetzt Registrieren 1

- General instructions 2

- Contents 3

- 1 Contents 3

- 2 Safety instructions 5

- Safety instructions 10

- Safety in 11

- Intended use 13

- 3 Intended use 13

- Machine description 16

- – quick overview 16

- 10.06.2013 17

- Design and function 20

- 5 Design and function 20

- Design and functi 25

- 6.1 General 35

- 6.3 Maintenance work 36

- 6.4 Disposing of equipment 37

- Rectifying faults 38

- 7 Rectifying faults 38

- Technical data 44

- 8 Technical data 44

- 9 Accessories 47

- Accessories 48

- Appendix A 49

- 10 Appendix A 49

- Appendix B 50

- 11 Appendix B 50

(211 pages)

(211 pages) (19 pages)

(19 pages)

Comments to this Manuals